Aluminium sheets have become one of the most widely used fabrication materials across industries. Known for their lightweight nature, strength, and excellent versatility, aluminium sheets are often preferred over traditional materials like steel or iron—especially in projects where durability and corrosion resistance are essential. Whether used in construction, automotive parts, electrical applications, or interior works, aluminium sheets continue to play a critical role in modern fabrication.

For businesses in Kuwait, aluminium sheets have gained even more relevance due to the country’s climate conditions, industrial growth, and demand for sustainable building solutions. Their adaptability, cost-effectiveness, and long-lasting performance make them a practical choice for fabrication projects of all sizes.

What is an Aluminum Sheet?

Aluminium sheets are thin, flat metal panels produced in various thicknesses and grades. They are known for being lightweight yet strong, making them ideal for both heavy-duty industrial applications and detailed architectural works. Because aluminium naturally forms a protective oxide layer, the sheets offer excellent corrosion resistance, even when exposed to moisture, chemicals, or harsh weather conditions.

From manufacturing machinery components to assembling decorative structures, aluminium sheets deliver unmatched performance and flexibility.

Properties of Aluminium That Make Them Ideal for Fabrication

Aluminium possesses a unique combination of properties that makes it a top choice for fabrication in nearly every industry:

1. Lightweight Yet Strong

Aluminium weighs approximately one-third of steel, making it easier to transport, handle, and install. Despite its low weight, it offers impressive strength suitable for structural and mechanical applications.

2. Corrosion Resistant

The metal naturally resists rust and corrosion, especially in humid or salty environments. This makes aluminium sheets a practical option for use in Kuwait’s coastal regions.

3. Excellent Workability

Aluminium can be cut, bent, welded, drilled, and shaped with ease. This makes it ideal for custom fabrication work, detailed designs, and complex structures.

4. Thermal and Electrical Conductivity

The metal conducts heat and electricity efficiently, making it suitable for HVAC systems, electrical panels, and heat exchangers.

5. Aesthetic Appeal

Aluminium sheets have a clean, modern look and can be anodized or coated for enhanced visual appeal, making them popular for interior and exterior design.

Types of Aluminium Sheets Offered by Century Steel in Kuwait

Aluminium sheets come in several types based on the grade, thickness, and intended application. Some of the most common varieties include:

Aluminium Plain Sheet

Lightweight, durable, and corrosion-resistant, perfect for construction, fabrication, automotive parts, signage, and engineering.

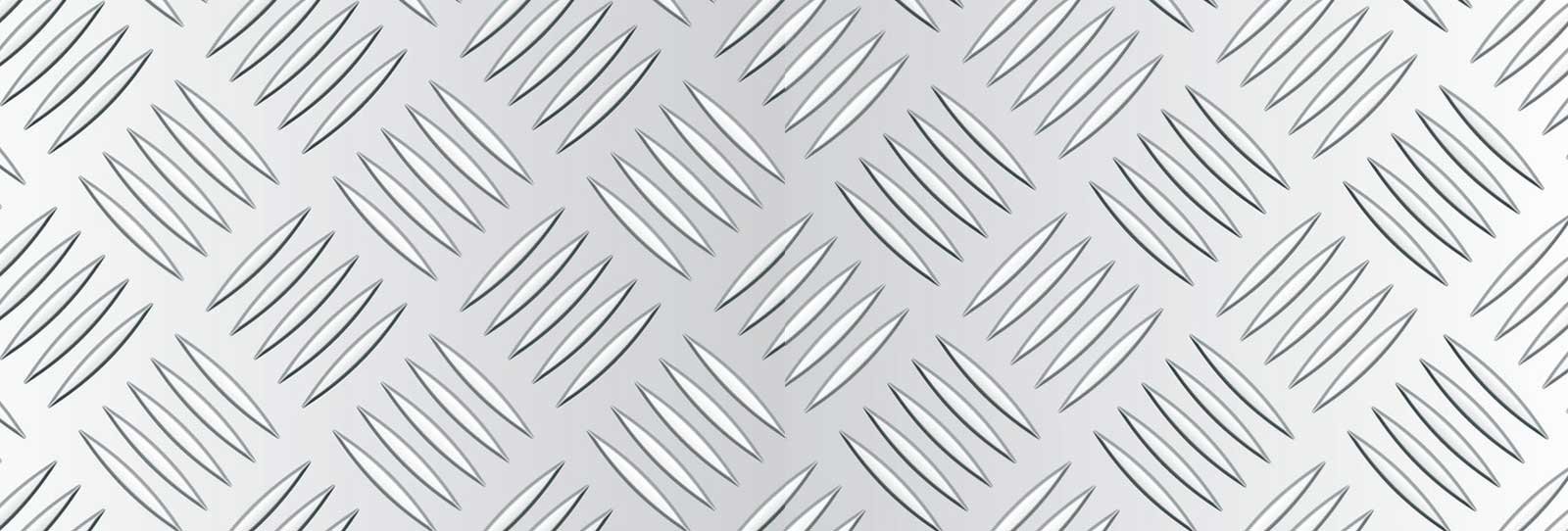

Aluminium Chequered Plate

Diamond-patterned surface for anti-slip flooring and enhanced safety in factories, trucks, and walkways.

Aluminium Composite Panel (ACP)

Lightweight cladding with a smooth finish, ideal for exterior façades, interior décor, signage, and architectural projects.

Each type is designed to meet specific fabrication needs, allowing industries to choose the ideal option for their projects.

Contact Century Steel today for high-quality aluminium sheet solutions. - Century Steel Brochure

Thickness & Size Options Available

Aluminium sheets are available in a variety of thicknesses, usually ranging from 0.5 mm to 6 mm. Thinner sheets are preferred for decorative or lightweight applications, while thicker ones are used for structural and industrial projects.

Standard sheet sizes often include:

- 4 ft × 8 ft (1220 mm × 2440 mm)

- 5 ft × 10 ft (1525 mm × 3050 mm)

However, custom sizing is also available depending on project requirements.

Choosing the right thickness and size ensures strength, stability, and suitability for fabrication needs.

Fabrication Processes Using Aluminium Sheets

Aluminium sheets are compatible with a wide range of fabrication processes, making them useful across industries. Common fabrication methods include:

- Cutting

Laser cutting, plasma cutting, and shearing methods are used to achieve clean, precise edges.

- Bending & Folding

Aluminium’s malleability allows it to be bent into various shapes without breaking, making it ideal for customized designs.

- Welding

TIG and MIG welding techniques are commonly used to join aluminium sheets for structural or mechanical assemblies.

- Punching & Drilling

These processes are used to create holes or slots needed for mounting, joining, or ventilation.

- Finishing

Anodizing, powder coating, and polishing improve durability and enhance visual appeal.

Applications Across Various Industries

Aluminium sheets are widely used in Kuwait’s major industries due to their strength, versatility, and corrosion resistance. Key applications include:

1. Construction & Architecture

Used in wall cladding, roofing, ceilings, window frames, and decorative panels.

2. Automotive & Transportation

Perfect for vehicle bodies, trailers, flooring, and protective coverings.

3. HVAC & Electrical

Used in ducting systems, air diffusers, electrical enclosures, and heat exchangers.

4. Marine & Coastal Structures

Ideal for use in humid or salty environments due to high corrosion resistance.

5. Furniture & Interior Design

Used in cabinets, partitions, signboards, and modern furniture elements.

Benefits of Using Aluminium Sheets in Fabrication

- Durability for Long-Term Performance

Aluminium’s strength and resistance to corrosion ensure long-lasting results.

- Easy to Work With

Fabricators prefer aluminium sheets because they simplify machining and installation.

- Lightweight Advantage

Reduced weight helps in easier transportation and lowers project costs.

- Cost-Effective Material

Compared to other metals, aluminium offers excellent performance at a competitive price.

- Eco-Friendly

Aluminium is 100% recyclable, supporting sustainable construction and manufacturing practices.

Why Choose Century Steel in Kuwait for Aluminium Sheets

Century Steel has built a strong reputation in Kuwait for supplying top-quality aluminium sheets suitable for fabrication projects across industries. With a focus on durability, precision, and customer satisfaction, Century Steel ensures consistent quality and timely delivery. Whether your project is small, large, simple, or highly customized, Century Steel provides the right aluminium sheet solutions tailored to your needs.

Maintenance & Care Tips

To extend the life of aluminium sheets:

- Clean regularly with mild soap and water

- Avoid abrasive cleaners that may scratch the surface

- Store sheets in a dry, covered area

- Apply protective coating if exposed to harsh environments

Proper care ensures long-lasting performance and preserves the appearance of the material.

Conclusion

Aluminium sheets remain a cornerstone of modern fabrication, valued for their versatility, durability, and ease of use. Whether for construction, automotive, interior design, or industrial projects, the right type, size, and grade can elevate both quality and performance. By choosing Century Steel in Kuwait, you ensure consistent, high-quality materials and reliable support for every project.

Contact us today to find the perfect aluminium sheet for your needs and take your fabrication work to the next level!